Renewable energy

Hydrogen energy

Hydrogen productoin

Renewable energy

Alternative energy

( EN ) PROCESS FOR PRODUCING HYDROGEN AND POWER SUPPLY APPARATUS ON THE BASIS THEREOF

And when you cut down the last tree, catch the last fish, drink the last drop of water

And when you cut down the last tree, catch the last fish, drink the last drop of water

- you finally realize that you can not eat gold.

ancient Native American prophecy.

Oil is not fuel - you can drown in banknotes.

D. Mendeleev

Only our ignorance leads us to use fossil fuels.

Konstantin Tsiolkovsky

Abstract

The invention relates to processes for producing hydrogen and the use of hydrogen in fixed and mobile power supply apparatuses. The technical result of the invention consists in reducing the costs of hydrogen production and reducing hazardous waste. According to the invention, hydrogen is produced during electrolysis by rotating a working substance in a fixed working chamber and separating said substance into an anion enriched substance and a cation enriched substance, which are then fed into discharge chambers. The working chamber is situated in orthogonal electric and magnetic fields, the magnetic field being directed parallel to the axis of rotation, and the electric field being directed radially from the periphery towards the centre of the working chamber. Energy transfer is performed not only by physical processes liquefaction-vaporization of the working body as in conventional compression heat pump and in the course of chemical reactions: endothermic - electrolysis of water (working fluid - electrolyte), and exothermic - the oxidation of hydrogen with oxygen - make up water. The process for producing hydrogen can be used in the power industry, in power supply apparatuses on vehicles with an ICE, steam and gas turbine arrangement, etc., such as land-based transport, watercraft and aircraft, and also for the supply of energy to buildings and constructions. The expected cost of hydrogen - 1,8$/kg ( $162/1000m3 ).

Description of the invention.

The invention can be used to produce hydrogen for stationary and mobile power plants that do not violate the ecology of the environment.

The invention relates to methods for producing hydrogen and its use. It is used in energy, transport, machine building, metallurgy, chemical industry, etc.

The transition to hydrogen energy can solve not only the problem of pollution from combustion of traditional fuels (coal, oil, gas, nuclear fuel), but also the problem of global warming, because it allows to utilize low-grade thermal energy gratuitous environment, turning it into high energy hydrogen fuel, which passes by oxidation or combustion to electric power, or perform mechanical work. Thus, the problem is to find the least costly method of obtaining energy of hydrogen. Hydrogen produced by electrolysis - of renewable resource that allows you to find natural, not renewable resources (coal, oil, gas) is more worthy use than just burning.

Hydrogen is the cleanest of all existing fuels. Hydrogen is an energy source as well as substance, and, by virtue of this dualism has complexing properties which can be built energoobespechivayuschih systems consisting of energy sources and energy production based on the consumption of hydrogen as a substance that is are part of the economy in a broader sense than just energy [ 1 ] .

The purpose of the present invention is to reduce the costs of high-grade energy for hydrogen production, reducing its value to sustainable levels, making it competitive with traditional energy sources like coal, oil, gas, nuclear fuel, will lead to wider use of it and, ultimately, transition to hydrogen energy - the hydrogen economy will help to reduce harmful emissions, the danger of global warming, improve the environment.

Methods of hydrogen production and use.

1. In industrial scale, hydrogen is produced by conversion of methane (SMR) or coal. At the inlet natural gas or coal, and steam - at the output of hydrogen and carbon dioxide. When SMR 50% hydrogen produced - through the water at steam reforming of coal - 100%. The cost of hydrogen is determined by the value of used resources, non-renewable, high-potential energy - natural gas or coal. Reserves are estimated to account for the different 40-80 years, and cost - tends to increase. Carbon dioxide requires additional energy consumption for recycling.

2. Hydrogen is also obtained by the electrolysis of water. At the entrance of the process water - electrolyte solution and an electric current, the output of hydrogen and oxygen. The electrolyte is not consumed during the reaction and acts as a catalyst. The cost of electrolytic hydrogen is much higher conversion. The lion's share of its cost - the cost of electricity consumed. For example, during a power failure, electric current of nuclear power plants is the production of hydrogen. This allows us not to reduce the reactor power, which increases the safety of nuclear power plants. Supply of hydrogen used during peak energy use. Thus Hydrogen acts as a energy storage. Steam electrolysis - a kind of conventional electrolysis. Part of the energy needed to split water, in this case is embedded in a high-heat steam heating (up to 900°C), making the process more efficient. Photolysis - Hydrogen can be produced in the absorption of water molecules energy 285.57 kJ/mol in the ultraviolet region. Catalysts have been developed allowing the water molecules absorb light in the visible region and decay. Thermolysis of water - when heated above 2500°C, water is decomposed into hydrogen and oxygen. The problem here is to prevent the recombination of hydrogen and oxygen [ 1 ] .

3. Known methods for producing hydrogen, increasing efficiency, using electromagnetic and acoustic waves or electric pulses of a certain frequency and power. They allow you to get Brown's gas (HHO), - an explosive mixture of hydrogen and oxygen. HHO is unstable - requires the immediate use by the oxidation or combustion, such as Stanley Meyer's cell generator, Willie Brown generator or alternator Oleg Kazakov, John Kanzius [ 5, 6, 7, 8 ] . Brown gas additive to the fuel in the engine leads to a more complete combustion, reducing toxic emissions.

4. Known devices used as power plants to hydrogen fuel for transport, for example, in motor vehicles - in the car Honda FCX [ 9 ] . But they need periodic refueling tanks at gas stations with compressed hydrogen, produced one of the industrial processes [ 1, 2, 3, 4 ] . Such a power plant contains a control block, a cylinder of compressed hydrogen, providing hydrogen fuel cell electric power which feeds through ultracapacitor electric drive train. Also known aerial vehicles. Experimental aircraft TU-155 [ 10 ] , which uses liquid hydrogen as fuel and requiring cryogenic technology to store it on board. Or experimental aircraft company Boeing [ 11 ] , which contains fuel cells that consume hydrogen, produce electricity and emit water at the outlet. Electricity is the fuel cell feeds the motor, the torque screw propulsion.

5. Known power plants that generate electricity - thermal power plants TPP [ 12 ] , using compressed natural gas, oil or coal dust. Products of their combustion, regardless of the applied cleaning methods will inevitably lead to environmental pollution, environmental degradation, greenhouse gas emissions. Nuclear power plants [ 13 ] is called clean, despite the need for disposal of spent nuclear fuel, not to mention the problems associated with disaster recovery. And thermal power plants, and nuclear power plants provide steam generator, turbine generator supply, which generates electricity. Steam parameters determine the efficiency of plant [ 14 ] . Steam generator uses the heat of combustion of one of the traditional fuels.6. Known power plants, producing energy that do not violate environmental harmful emissions: a mini-OTEC, OTEC-1, and others on the program OTEC (Osean Thermal Energy Conversion). They work like a heat engine,- on temperature difference between the upper and lower - warm and cold sea water layers [ 15, 16 ] . Their effectiveness is fairly low - most of the energy produced is consumed by the very setting for the pump drive water circulation, so these units are more experimental than the industry. To clean energy facilities also include wind, solar, geothermal, tidal, osmotic, wave, hydro-power plants, although many of them have their drawbacks.

7. Known natural processes of photosynthesis of organic compounds - sugars and starches from carbon dioxide and water with oxygen in the grains of chlorophyll under the influence of solar radiation [ 17 ] . The energy received by mankind burning fossil fuels (coal, oil, natural gas, peat) is also stored in the process of photosynthesis. In the late 90s of the twentieth century, it was shown that under conditions of sulfur deficiency biochemical oxygen production process, ie normal photosynthesis is switched to the production of hydrogen [ 18 ] .

8. Theoretically, the source of heat is any body with a temperature above absolute zero, T> -273°C. In practice, the source of heat energy - the body whose temperature can be lowered by several degrees without damage to the environment, at a cost of some energy. The ratio of the resulting thermal energy is expended to - coefficient of performance (COP). Known heating and air conditioning systems for industrial and domestic premises, working on heat pumps [ 19, 20 ] , pumping heat into the room environment, or vice versa (air conditioners). For today's heat pumps COP value is 3-6.

9. Known technical solution - "elektrovodorodny Studennikova generator" (EVG) - the application of RU98/00190 07/10/1997, patents RU 2003104497/12 on 17.02.2003, PCT/RU 03/00413 of 18.09.2003, which increases the efficiency of hydrogen production. In the EVG is used for electrolysis is the separation of ions in the electrolyte due to centrifugal inertial force produced by the rotation of the working chamber with electrolyte - slow electrolysis [ 21, 22 ] .

10. The closest technical solution to the claimed invention is "a device for the electrolytic production of hydrogen and oxygen" patent RU 2309198 C1 10/27/2007 by [ 27 ] . To increase the efficiency of hydrogen electrolysis is performed in the cell with the conductive lid and electrodes, rotating between the magnets of an electromagnetic system. The heat expended in this case is supplemented with water coming into the cell through the exchanger.

The disadvantages of this device are:

10.1. The top 3 and bottom 4 cover a cell 1 made of electrically conductive material, and when rotated in a magnetic field in them, induced eddy currents - Foucault currents, leading to heat up, slowing down the rotation of the electrolyzer 1, reduce the efficiency, productivity and efficiency of the device. That is, decrease in the rate of rotation does not lead to greater efficiency.

10.2. To connect the channels made in the shaft 5 cell 1, a supply of water and electrolyte 9 and removal of electrolysis products with 10 production lines supply 13 and 22 respectively removal, would require a mobile rotary seals for aggressive environment - an electrolyte, which reduces the reliability of the device and the safety of its operation.

10.3. The products of electrolysis - oxygen-hydrogen mixture flowing from cell 1 (on channels 10 and 22), a thundering gas, posing a threat, requires the use of a separator 25 for separating a mixture of hydrogen and oxygen. This complicates and increases the cost of the device and reduces its reliability and operating safety.

10.4. Chain ions in the cell 1 discharge between the electrodes 2 and 11 is made through the top 3 and bottom 4 covers - current is closed through the cage housing the electrolyzer 1. This makes the process of electrolysis of control, - are controlled by only indirect indicators.

10.5. According to the description of processes occurring in the prototype "... rotating electrolyzer 1, to the extent of decomposition of water, increasing the concentration of the electrolyte and reduce its volume, the electrode 11, located on the shaft 5 is in a gaseous medium and the electrolysis is terminated. The signal analyzer with 24 opens the device controlling the flow of water from the tank 19 and 20 on the production line 13 into the cell enters a heated water in a heat exchanger 14. Then the process repeats itself.". Such a periodic interruption of the electrolysis process also reduces the performance of the device

10.6. As described [ 27 ] - electrolyte electrolyzer once filled out a tank 17 through valve 16, a mixer 15 and the heat exchanger 14, then valve 16 is blocked and the water supply valve 18 - open, and then, at work, as the decomposition of water into hydrogen and oxygen and pump a mixture of pumping device 23 products of electrolysis, electrolytic cell 1 is replenished by water from the tank 20 through the flow control device 19, controlled by a gas analyzer 24, valve 18, mixer 15 and the heat exchanger 14. Thus, from the viewpoint of thermodynamics, the rate at which heat water in an electrolytic cell 1 is equal to the rate of energy consumption for electrolysis the same amount of water. Coblyudenie law of conservation of energy demand from the heat exchanger operating conditions difficult to be realized - the water temperature at the exit of T~3000°C. On the other hand, to increase the efficiency of heat exchange in heat exchanger 14 will require a higher circulation rate of the components between which the heat transfer - far surpassing the rate of flow of water by electrolysis. Thus rate of replenishment of water is insufficient, because circuit is not closed, which greatly reduces the performance of the device

The inherent disadvantages of the prototype does not allow you to fully realize the goal - reducing energy consumption for hydrogen production.

The proposed method of producing hydrogen by electrolysis is the pre-separation of ions in the electrolyte is not only rotating in a field of centrifugal inertial forces (forces of artificial gravity) due to the difference of their masses,

![]() at the same time, the heavy ions move to the periphery, displacing light ions to the center - in the zone axis of rotation. A similar method is used to separate isotopes of uranium in centrifuges at its enrichment for energy and weaponry. The separation of ions occurs in orthogonal electric and magnetic fields, which are also orthogonal to the direction of the electrolyte (the ion velocity vector), in particular, the magnetic field oriented parallel to the axis of rotation, and the electric field is directed radially from the periphery to the center of the working chamber. Thus, the ions are still valid and the Lorentz force, and the division is also due to differences in the signs of the charges of the ions.

at the same time, the heavy ions move to the periphery, displacing light ions to the center - in the zone axis of rotation. A similar method is used to separate isotopes of uranium in centrifuges at its enrichment for energy and weaponry. The separation of ions occurs in orthogonal electric and magnetic fields, which are also orthogonal to the direction of the electrolyte (the ion velocity vector), in particular, the magnetic field oriented parallel to the axis of rotation, and the electric field is directed radially from the periphery to the center of the working chamber. Thus, the ions are still valid and the Lorentz force, and the division is also due to differences in the signs of the charges of the ions.

![]() Orthogonal fields are used, for example, in devices for desalination of sea water

[ 23 ]

, magnetic water treatment, vacuum tube microwave - magnetrons used in radar, microwave ovens, cyclotrons - particle accelerators, MHD generators. Thus, under the action of the vector sum of two forces is the magneto-hydrodynamic separation of ions. Rotation of the electrolyte in the chamber also leads to the elimination of over-voltage, resulting from the polarization of the electrodes, cleaning of the electrode surface from the reaction products during the electrolysis and, consequently, to reduce energy consumption. Neutralization of the charges of the ions, after their separation occurs in the work and in the discharge chamber, where the ions are reduced to neutral atoms and molecules.

Orthogonal fields are used, for example, in devices for desalination of sea water

[ 23 ]

, magnetic water treatment, vacuum tube microwave - magnetrons used in radar, microwave ovens, cyclotrons - particle accelerators, MHD generators. Thus, under the action of the vector sum of two forces is the magneto-hydrodynamic separation of ions. Rotation of the electrolyte in the chamber also leads to the elimination of over-voltage, resulting from the polarization of the electrodes, cleaning of the electrode surface from the reaction products during the electrolysis and, consequently, to reduce energy consumption. Neutralization of the charges of the ions, after their separation occurs in the work and in the discharge chamber, where the ions are reduced to neutral atoms and molecules.

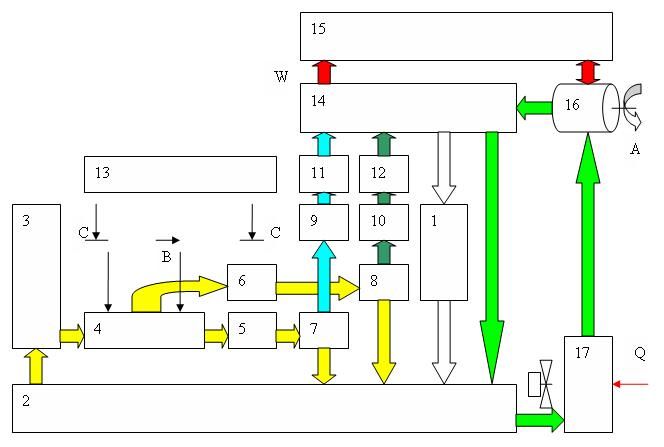

A method of producing hydrogen work demonstrates the power plant (Fig. 1), which is a heat pump.

The working substance - an electrolyte circulating in the first working circuit by a pump 3 from the heat exchanger 2 is applied to the working chamber 4, where the working medium is rotated in a magnetic field, orientation of rotation axis and the electric field E, the orientation in the direction from the periphery to the center working chamber - the axis of rotation. Thus, there is a separation of ions by the centrifugal inertial force due to the mass difference between ions and the Lorentz force due to the difference in the signs of the ion charge. Concentration of light, positively charged ions - cations increases in the center, near the axis of rotation, where there is a partial neutralization of the ions. Further, the working medium, enriched with ions of opposite sign, falls into the discharge chambers 5, 6, where the ions of the electrolyte is neutralized, losing its charges by absorbing heat while working substance, and there are further, separators, dryers, gas circuit breakers continuity of the flow 7, 8, where gas is separated from the working substance, which returns to the coolant heat exchanger 2, and with increasing electrolyte concentration or decreasing its level of the electrolyte in the heat exchanger 2 is replenished with solvent - distilled water from the tank 1. Gases - hydrogen and oxygen from the separators, dryers, choppers continuity of the flow 7, 8, through check valves 9, 10 and sensors and gas analyzers, volume 11, 12 are fed to the fuel cell 14, where hydrogen is oxidized to water which is returned on the first working circuit heat exchanger 2 through the tank 1 (recovery of water). Electricity W, generated by the fuel cell 14, charges the ultracapacitor buffer 15, the feed motor 16, which produces mechanical energy of A, doing the work, or in recovery mode, the electric motor 16 operates as a generator of electricity and adds W ultracapacitor 15. Endothermic process of water electrolysis

[ 24 ]

, proceeds with the absorption of heat of the working substance, which is compensated by a heat exchanger, two coolant of the second circuit, pumping warm environment Q, with a heat exchanger of the second circuit 17, as well as the warmth of allocated motor 16 and the fuel cell 14 (heat recovery QR) the working substance. Modes of operation (temperature, pressure, speed, concentration of the working substance at the control points and the parameters of consumption and the resulting electrical current) are controlled by control unit 13, - communication control unit 13 to the power plant units (Fig. 1) to simplify the scheme conventionally not shown . In some cases, the fuel cell 14, ultracapacitor 15 and motor 16 may be replaced by the thermal engine - the traditional internal combustion engines, turbine generators, diesel generator, PSTU, or MHD generator in combination with PSTU. In their work for the oxidation (combustion) of hydrogen can also be used and oxygen in the air. Therefore, the power plant units 1-13 and 17 can be arbitrarily combined into one functional unit - hydrogen generator, heat pump, which converts the heat of the environment into high energy of hydrogen, which, in turn, can be used arbitrarily preobrazavatelem fuels into mechanical or electrical energy, or consumers of hydrogen and oxygen for technological purposes.

The working substance - an electrolyte circulating in the first working circuit by a pump 3 from the heat exchanger 2 is applied to the working chamber 4, where the working medium is rotated in a magnetic field, orientation of rotation axis and the electric field E, the orientation in the direction from the periphery to the center working chamber - the axis of rotation. Thus, there is a separation of ions by the centrifugal inertial force due to the mass difference between ions and the Lorentz force due to the difference in the signs of the ion charge. Concentration of light, positively charged ions - cations increases in the center, near the axis of rotation, where there is a partial neutralization of the ions. Further, the working medium, enriched with ions of opposite sign, falls into the discharge chambers 5, 6, where the ions of the electrolyte is neutralized, losing its charges by absorbing heat while working substance, and there are further, separators, dryers, gas circuit breakers continuity of the flow 7, 8, where gas is separated from the working substance, which returns to the coolant heat exchanger 2, and with increasing electrolyte concentration or decreasing its level of the electrolyte in the heat exchanger 2 is replenished with solvent - distilled water from the tank 1. Gases - hydrogen and oxygen from the separators, dryers, choppers continuity of the flow 7, 8, through check valves 9, 10 and sensors and gas analyzers, volume 11, 12 are fed to the fuel cell 14, where hydrogen is oxidized to water which is returned on the first working circuit heat exchanger 2 through the tank 1 (recovery of water). Electricity W, generated by the fuel cell 14, charges the ultracapacitor buffer 15, the feed motor 16, which produces mechanical energy of A, doing the work, or in recovery mode, the electric motor 16 operates as a generator of electricity and adds W ultracapacitor 15. Endothermic process of water electrolysis

[ 24 ]

, proceeds with the absorption of heat of the working substance, which is compensated by a heat exchanger, two coolant of the second circuit, pumping warm environment Q, with a heat exchanger of the second circuit 17, as well as the warmth of allocated motor 16 and the fuel cell 14 (heat recovery QR) the working substance. Modes of operation (temperature, pressure, speed, concentration of the working substance at the control points and the parameters of consumption and the resulting electrical current) are controlled by control unit 13, - communication control unit 13 to the power plant units (Fig. 1) to simplify the scheme conventionally not shown . In some cases, the fuel cell 14, ultracapacitor 15 and motor 16 may be replaced by the thermal engine - the traditional internal combustion engines, turbine generators, diesel generator, PSTU, or MHD generator in combination with PSTU. In their work for the oxidation (combustion) of hydrogen can also be used and oxygen in the air. Therefore, the power plant units 1-13 and 17 can be arbitrarily combined into one functional unit - hydrogen generator, heat pump, which converts the heat of the environment into high energy of hydrogen, which, in turn, can be used arbitrarily preobrazavatelem fuels into mechanical or electrical energy, or consumers of hydrogen and oxygen for technological purposes.

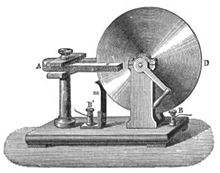

By clarifying the principle of the proposed hydrogen generator can be approached from the other side. A device that can be used as a current generator, and a motor - drive of Faraday, or "unipolar dynamo" Nikola Tesla

[ 25,

26 ]

, in which the conductor, a copper disc rotating in a magnetic field oriented parallel to the axis of rotation and electric current removed from the points located in the center - on the axis and on the periphery - the rim of the disc. Homopolar generator is characterized by: low EMF (several volts) with low internal resistance and high current, performance during the rotation of the magnet (magnetic field) along with the disk, relative to a stationary current collection - the paradox of Faraday, the lack of reaction on the disk current collection. In the claimed invention as a conductor disk, use an electrolyte - "drive from the electrolyte", in a rotating magnetic field and electric field arises due to the action of Lorentz force separating the charge carriers - ions of opposite sign, between the rim - the edge of the disk (anions) and its center (cations). These space charges and create an electric field, causing the current between edge and center of the disk to the external electrical circuit, restoring, so the ions to neutral molecules - hydrogen and oxygen, ie creates the conditions for the reaction of the electrolysis.

By clarifying the principle of the proposed hydrogen generator can be approached from the other side. A device that can be used as a current generator, and a motor - drive of Faraday, or "unipolar dynamo" Nikola Tesla

[ 25,

26 ]

, in which the conductor, a copper disc rotating in a magnetic field oriented parallel to the axis of rotation and electric current removed from the points located in the center - on the axis and on the periphery - the rim of the disc. Homopolar generator is characterized by: low EMF (several volts) with low internal resistance and high current, performance during the rotation of the magnet (magnetic field) along with the disk, relative to a stationary current collection - the paradox of Faraday, the lack of reaction on the disk current collection. In the claimed invention as a conductor disk, use an electrolyte - "drive from the electrolyte", in a rotating magnetic field and electric field arises due to the action of Lorentz force separating the charge carriers - ions of opposite sign, between the rim - the edge of the disk (anions) and its center (cations). These space charges and create an electric field, causing the current between edge and center of the disk to the external electrical circuit, restoring, so the ions to neutral molecules - hydrogen and oxygen, ie creates the conditions for the reaction of the electrolysis.

Since water is weakly dissociated and is not a conductor, then for the reaction of the electrolysis the working substance is an electrolyte - a solution of base, salt or acids such as bromine acid - HBrO3, sulfuric acid - H2SO4 or phosphoric acid - H3PO4, in which the mass ratio of ions is – H+ / BrO3- = 1 / 128, H+ / SO42- = 1 / 96, H+ / PO43- = 1 / 95, respectively, excluding the mass shell of the hydrated ions, such as hydronium H3O+, and more complex - H5O2+, H7O3+, H9O4+, etc. It should be noted that the ions as hydrated acid residue. Acid in the electrolyte is not consumed, but only participates in the reaction of the electrolysis by the scheme [ 21, 22 ] :

| Table 1. Chemical reactions in the hydrogen generator - heat pump (HP). | |||

| Working substance - electrolyte | HBrO3 | H2SO4 | H3PO4 |

| In solution | HBrO3 → H+ + BrO3- | H2SO4 → 2H+ + SO42- | H3PO4 → 3H+ + PO43- |

| At the cathode | 2H+ + 2е- → H2↑ | 2H+ + 2е- → H2↑ | 2H+ + 2е- → H2↑ |

| At the anode | 2BrO3- - 2е- → 0,5O2↑ + Br2O5 | SO42- - 2e- → 0,5O2↑ + SO3↑ | 4PO43- - 12е- → 3O2↑ + 2P2O5 |

| In the anode space of the reaction residue with water | Br2O5 + H2O → 2HBrO3 HBrO3 → H+ + BrO3- |

SO3 + H2O → H2SO4 H2SO4 → 2H+ + SO42- |

P2O5 + 3H2O → 2H3PO4 H3PO4 → 3H+ + PO43- |

| Table 2. The chemical reactions in the fuel cell (FC), or a heat engine (HE). | |||

| At the anode | H2 → 2H+ + 2е- | H2 → 2H+ + 2е- | H2 → 2H+ + 2е- |

| At the cathode | 4H+ + 4е- + O2 → 2H2O | 4H+ + 4е- + O2 → 2H2O | 4H+ + 4е- + O2 → 2H2O |

H2O(L) = electrolysis reactions > H2(G) + 0,5O2(G) – qH – reaction in the hydrogen generator

H2(G) + 0,5O2(G) = oxidation > H2O(G) + qL – reaction in a fuel cell or heat engine

H2O(G) = condensation > H2O(L) + qF + с ΔT m – condensation of steam and cooling,

where qH and qL - respectively the upper and lower specific heat of combustion of hydrogen or her equal and opposite in sign, the enthalpy of formation water and its component Gibbs energy, called the free energy, and qF - the heat of the phase transition water-vapor or latent heat of vaporization of water. Energy source is a gratuitous low-grade heat of the environment - in the long run, the accumulated energy of the sun - the heat of the earth, water, air and heat pump only pumps it into the potential energy of hydrogen, electricity or mechanical (depending on demand) and, when performing a useful work is converted into heat, which is returned to the environment, according to the law of conservation of energy. In addition to the heat of the environment - sun, water, geothermal, soil, etc., can also utilize the heat of the technological processes, cooling industries, industrial power generating stations, swimming pools, cooling - thermal power plants, nuclear power plants, DIC, etc. ., which are now released into the atmosphere.

The use of a hydrogen generator and power plant based on it.

Some examples of the hydrogen generator, heat pump, heat exchanger which can use the thermal energy: the ground (placed in the wells, pile foundations of buildings and structures, soil, or coolers), water (local water bodies, groundwater, river water, coastal water, warm currents of water, geothermal); air (air cooling), Sun (solar collectors), wind energy, heat or dispose of industrial process plants. The additional flow of energy for heat pump provides heat recovery, resulting in compression or liquefaction of hydrogen and oxygen for storage or transport. Experience in operating heat pumps [ 19, 20 ] shows that the heat exchanger in the hole you can shoot 60 W/m thermal power without sacrificing the heat balance of soil, whereas at a depth of 170 m wells and step between 10 m and each 1 km2 of land provides 100 MW thermal power, while the ground remains suitable for agricultural use - without the danger of turning it into the permafrost. The energy is literally under our feet.

Chemical industry. Hydrogen - the raw material for the production of ammonia.

Metallurgy. Using hydrogen for smelting (restoration) of pure metals.

Energetics. Gas turbines with heat recovery boiler (steam generator using heat of exhaust gases) and an additional steam turbine efficiency can have more than 40% (PSTU). In nuclear power plants operating at lower temperatures and pressures, a slightly smaller total efficiency - about 32%. Thermal efficiency of steam turbine power plant is greater than the higher operating temperature and vapor pressure. If at the beginning of the twentieth century. these parameters were 1.37 MPa and 260°C, it is now common in pressure over 34 MPa and temperatures above 590°C (NPP operate at lower temperatures and pressures than the largest thermal power plant, because regulations limited the maximum allowable temperature of the reactor core) . In modern steam power plants steam, partly in the exhaust turbine, shown in its staging point for re-heating (reheat) to the initial temperature, and may include two or more stages of reheat. Pairs of other points of the turbine is given to preheat the feed water supplied to the steam generator. Such measures are much increased thermal efficiency [ 14 ] . In the existing nuclear power plants in the first stage, hydrogen generator, heat pump, utilizing the heat of the reactor and generates steam for turbine generators, will significantly improve efficiency by increasing the temperature and vapor pressure, as well as smooth out peak loads associated with the diurnal and seasonal variations of which increases safe operation of the reactor. In the second stage, after the establishment of a resource the nuclear reactor, the hydrogen will move completely ES for recycling the heat of the environment, dismantling, or preservation of the reactor. Also, hydrogen generator, a heat pump can provide stationary and mobile fuel power plants with internal combustion engines, turbine generators, diesel generators, PSTU, turbofan, MHD generators with PSTU, without significant alterations will translate the existing thermal power plants [ 12 ] on hydrogen fuel, reducing harmful emissions - improving the environment. Since the combustion of hydrogen is water vapor T ~ 3000°C, then adding water to the combustion chamber helps to reduce its temperature to increase pressure and cause steam parameters to the requirements of the turbine or another user, use PSTU with temperature before the turbine T-900-1200°C and efficiency of ~ 60 % or more [ 28 ] .

Transportation. In the application of a hydrogen generator, a heat pump in the ground and air transport of the second circuit coolant is air, so the determining factor is the heat exchanger - its productivity, efficiency and size. As an alternative to the mobile hydrogen generator, the variant of the stationary hydrogen generators located at gas stations and provides a vehicle fuel - compressed hydrogen or a compound - ammonia [ 1 ] . The water transport - surface and underwater, the second circuit coolant is water, so the use of a hydrogen generator, a heat pump requires an effective de-icing systems in a heat exchanger and means of protection against fouling. In order to reduce acoustic noise and increase efficiency, traction may be water cannons or screws in the ring shaped fairings - fenestronah performed as heat exchangers.

Construction. Hydrogen generator, a heat pump can be used in autonomous systems of energy supply, heating, air conditioning, ventilation, domestic and industrial buildings.

The essence of the invention:

1. A method of producing hydrogen, based on a inertial electrolysis - the rotation of the working substance in the chamber, and the use of centrifugal inertial force acting on the ions of different mass to separate them. Additionally, the working chamber is placed in orthogonal electric and magnetic fields so that the magnetic field is parallel to the axis of rotation of the working substance, and the electric field is directed radially from the periphery to the center of the working chamber, thus, under the action of the vector sum of the Lorentz force and the centrifugal inertial force, a negative charged, heavy ions - anions are displaced to the periphery of the working chamber, and the positively charged, light hydrogen ions - cations - to the center, the zone axis of rotation, ie, a magneto-hydrodynamic separation of the working substance in two isolated stream: enriched anions and cations, then passing through the release of oxygen and hydrogen, respectively, thereby reducing the rotational speed of the electrolyte and, consequently, the energy expenditure required to produce hydrogen.

2. The working chamber a hydrogen generator, a heat pump is made stationary, it provided the rotation of the working substance due to its circulation in the first working circuit that can eliminate the strain arising from a polarization of the electrodes, clean surface of the electrodes from the reaction products during electrolysis - to reduce energy consumption, excluding construction of the working chamber seals and leakage characteristic of them working substance and the reaction products of electrolysis, increasing the reliability of the hydrogen generator, heat pump and the safety of its operation.

3. The method of hydrogen production based on electrolysis - the discharge (charge neutralization) ions, which occurs in the work, and in the discharge chamber, so that there is no bypass circuit discharge of ions of the working chamber walls. Separation of ions by the Lorentz force and the centrifugal inertial force, creates the opposite in sign to the space charge (Fig. 1, C-C) at the periphery and the center of the working chamber, between which an electric field Ei, by inducing an electric double layer (EDL) charge electric field E, which generates an electric current in an external circuit that performs the discharge of ions, that is, creates conditions for the electrolysis reaction, which occurs in the working chamber and the discharge chamber, providing monitoring and control process.

To ensure the autonomy of the work, reducing harmful emissions, operating costs, improve reliability and safety of operation:

4. Environmentally friendly power plant, heat pump uses a hydrogen generator based on the method of subsections. 1-3 and perform the transfer of heat energy environment in the potential energy of hydrogen in a chemical reaction endothermic electrolysis <-> oxidation, and then into electrical energy and mechanical energy, and includes (Fig. 1) tank 1, the first circuit heat exchanger 2, the pump 3, the working chamber 4 in the magnetic field B parallel to the axis of rotation orientovanom working medium and the electric field E is directed radially from the periphery to the center of the working chamber, so that the ions act vector sum of the centrifugal inertial force and the Lorentz force, the two discharge chambers 5, 6, two separator - dryer gas - breaker continuous flow of working medium 7, 8, two check valves 9, 10, two sensors and the volume of the gas analyzer 11, 12, the fuel cell 14, 15 ultracapacitor electric motor 16, a heat exchanger of the second circuit 17, control unit 13 .

5. In the clean power plant, heat pump units 1-13 and 17 can be arbitrarily combined into one functional unit - hydrogen generator, heat pump, which converts the heat of the environment into high energy of hydrogen, which, in turn, can be used arbitrarily preobrazavatelem fuel energy into mechanical, or electrical energy, or consumers of hydrogen and oxygen, as agents for technological purposes, such as internal combustion engines, turbine generators, diesel generators, PSTU, turbofan, MHD generators with PSTU will allow without significant alteration of existing thermal power plant boilers convert to hydrogen fuel, reducing emissions, improving the environment. Since the combustion of hydrogen (T ~ 3000°C) is water vapor, the addition of water into the combustion chamber and the turbine reduces its temperature, pressure increases and leads to a pair of parameters required for optimum turbine or any other consumer.

6. Water vehicle - a ship or submarine power plant using hydrogen generator for supplying the engines (turbo or PSTU) traction drive propellers or water jets that perform well as forced circulation of water (sea, river or, utilizing its heat) along the boards, or in the channels (niches), below the waterline, where the hydrogen generator heat exchangers, heat pump, with appropriate de-icing systems, and protection from fouling the heat exchanger. In order to reduce acoustic noise and increase efficiency, traction may be water cannons or screws in the ring shaped fairings - fenestronah performed as heat exchangers.

7. Ground or air transport - rail, road or air transport, using the power plant generator for hydrogen, the supply traction motors (internal combustion engines, diesel generator, Turbofan). Engines and vehicle body surface contain air heat exchangers (with forced air pumping, or the oncoming flow speed), utilizing the heat of the air. Provides for a de-icing systems in heat exchangers.

8. Domestic or industrial autonomous heating system, air conditioning, ventilation, power supply buildings, power plant using the hydrogen-generator for heat pump, heat exchangers, which use heat: the earth (located in the wells, pile foundations of buildings and structures, ground or coolers), water (local water bodies, groundwater, river water, coastal water, the warm ocean currents and geothermal sources), air (air cooling), Sun (solar collectors), wind energy, heat or dispose of industrial production processes, data processing centers (DPC).

Compared with the prototype [ 27 ] , the proposed power plant on the generator hydrogen-heat pump has the following significant differences:

1. first working circuit is closed;

2. working substance circulates in the first working circuit;

3. working chamber is stationary;

4. working substance is rotated in the chamber, because of its circulation in the first working circuit;5. The working chamber is in a magnetic field;

6. in the chamber under the action of the vector sum of the Lorentz force and the centrifugal inertial force due to the difference in the signs of the charges and the difference in the masses, there is a magneto-hydrodynamic separation of the working substance in two isolated stream: enriched with anions and cations, then passing through the release of oxygen and hydrogen, respectively;

7. electrolysis takes place in the working, and in the discharge chamber;

8. due to rotation of the working substance and its circulation in the loop electrode is cleaned by electrolysis products, reduced strain;

9. discharge current flows through the external circuit, and shunted the walls of the working chamber;

10. control unit controls the parameters in checkpoints and manages the process of electrolysis;

11. working material serves as an electrolyte - in the process of electrolysis, and the coolant circulating in the loop - in the process of transfer of thermal energy;

12. energy converted into potential energy of hydrogen and oxygen by electrolysis, filled in a heat exchanger in the circulation through it of the working substance, by the thermal energy of the environment, according to the law of conservation of energy, and energy transfer occurs during the electrolysis reaction <-> oxidation;

Literature

1. Водород как энергоноситель с высокими экологическими свойствами. site

http://b-energy.ru/popularecology/53-hydrogen.html?tmpl=component&print=1&layout=default&page=

2. Высокоэффективный электролиз воды. site

http://alexfrolov.narod.ru/ruswater.htm

3. Водородная энергетика. Получение водорода. site

http://www.abitura.com/modern_physics/hydro_energy/hydro_energy5.html

4. Альтернативные источники энергии. Способы добычи водорода. site

http://www.takealtenergy.com/hydrogen/geth.html

5. Вечная энергия Казакова (получение водорода). site

http://www.skif.biz/index.php?name=Pages&op=page&pid=148

6. Генератор газа Брауна. sites

http://sds-max.com.ua/braun.html

,

http://x-faq.ru/index.php?topic=53.0;wap2

7. Генератор водорода Джона Канзиуса. site

http://vpl54.narod.ru/ERA_VODORODA.html

8. Топливная ячейка Мейєра. sites

http://prometheus.al.ru/phisik/meyer.htm

,

http://kotelok.info/index.php?name=Pages&op=page&pid=123

9. Honda FCX на топливных элементах. site

http://autolenta.ru/147.html

10. ТУ–155, site

http://www.airwar.ru/enc/xplane/tu155.html

11. Чистый полет: Самолет на водороде. site

http://www.popmech.ru/article/3231-chistyiy-polet/

12. Трипільська ТЕС. site

http://www.centrenergo.com/ukr/tripoly.html

13. Реактор РБМК – 1000. site

http://www.liveinternet.ru/community/1229387/post51428326/

14. Электрическая энергия. site

http://www.krugosvet.ru/enc/nauka_i_tehnika/fizika/ELEKTRICHESKAYA_ENERGIYA.html

15. Градиент–температурная энергетика (системы ОТЕС). site

http://www.greenenergy.com.ua/gradient-temperaturnaya-energetika-sistemy-otes/

16. Тепловая энергия океана. site

http://watervigorous.com/termo.htm

17. Фотосинтез. site

http://ru.wikipedia.org/wiki/Фотосинтез

18. Биотехнологическое получение водорода. site

http://ru.wikipedia.org/wiki/Биотехнологическое_получение_водорода

19. Принципы работы теплового насоса. site

http://www.budynok.kiev.ua/printsipyi-rabotyi-teplovogo-nasosa/

20. Принцип работы теплового насоса. sites

http://atmosystems.com.ua/how/

,

http://www.eco-therm.com.ua/principle.html

21. Электроводородный генератор (ЭВГ). заявка RU98/00190 от 07.10.1997, патент RU2003104497/12 от 17.02.2003. site

http://ikar.udm.ru/sb18-2.htm

22. Центробежный электроводородный генератор. патент PCT/RU 03/00413 от 18.09.2003. site

http://www.skif.biz/index.php?name=Pages&op=page&pid=43

23. Устройство для непрерывной переработки морской воды…, патент RU2199492. site

http://www.ntpo.com/patents_gas/gas_1/gas_71_1.shtml

24. Новая теория электролиза воды. site

http://www.inauka.ru/blogs/article80305/print.html

25. Заметки по поводу униполярной динамо–машины. site

http://serge.raikevich.com/tesla/13.htm

26. Бестопливный генератор Тесла. site

http://masterbiz.info/generator.tesla.htm

27. Устройство для электролитического получения водорода и кислорода. патент RU2309198 С1 от 31.01.2006. site

http://www.ntpo.com/patents_gas/gas_1/gas_113.shtml

28. Как поджечь и не взлететь. site

http://www.strf.ru/material.aspx?CatalogId=222&d_no=12057

Claim

1. A method of producing hydrogen, electrolysis based on an inertia - rotation of the working substance in the field of centrifugal inertial force and the magnetic field, characterized in that in order to: reduce energy consumption for hydrogen production, speed of the electrolyte, separating it into two streams - anions and cations , clean the electrode surface by electrolysis products, simplify the design of monitoring and control process of electrolysis, reliability and safety of operation; circulation of the working substance - of the electrolyte in the first working circuit, leads to its rotation in a stationary working chamber, located in orthogonal electric and magnetic fields so that the magnetic field is parallel to the axis of rotation of the working substance, and the electric field is directed radially from the periphery to the center of the working chamber so that the action of the vector sum of the Lorentz force and the centrifugal inertial force due to the difference in the signs of the charge and differ in mass, negatively charged, heavy ions - anions are displaced to the periphery of the working chamber, and the positively charged, light hydrogen ions - cations - to the center, the zone axis of rotation, ie is magnetohydrodynamic separation of ions in the two isolated flux, with electrolysis - the neutralization of the charges of the ions occurs in the work, and in the discharge chamber, due to current flow in the external electric circuit and exclusion bypass the walls of the working chamber, and the consumption of energy during the endothermic reaction of electrolysis converted into potential energy of hydrogen and oxygen in the heat exchanger is compensated by the thermal energy of the environment, according to the law of conservation of energy.

2. The heat pump that performs the transfer of energy by the circulation of the working substance in the circuit, characterized in that in order to ensure autonomy, efficiency, productivity, reliability, as the working substance is used electrolyte, and energy transfer is performed during the endothermic reaction of electrolysis to produce hydrogen and oxygen as a high-energy fuels, hydrogen generator, performed by the method according to claim 1, and the exothermic oxidation reaction of hydrogen with oxygen to produce water with an electrical or mechanical energy, respectively, in a fuel cell or heat engine.

3. The power plant, which contains the control unit, a cylinder of compressed hydrogen, providing hydrogen fuel cell electric power which feeds through ultracapacitor electric motor, characterized in that in order to ensure autonomy and reduced operating costs, improve operational reliability, instead of the cylinder with compressed hydrogen is used hydrogen generator based on the method for producing hydrogen according to claim 1 which acts as a heat pump according to claim 2, the transfer of low-grade heat energy environment in the potential energy of hydrogen in a chemical reaction endothermic electrolysis <-> oxidation, and then into electrical or mechanical energy and includes (Fig. 1) tank 1, the first circuit heat exchanger 2, pump 3, the working chamber 4 in a magnetic field oriented parallel to the axis of rotation of the working medium and the electric field E is directed radially from the periphery to the center of the working chamber, so that acting on the moving ions vector sum of the centrifugal inertial force and the Lorentz force, which provides a magneto-hydrodynamic separation of ions in the two isolated flow-rich anions and cations, two discharge chambers 5, 6, two separator - dryer gas - breaker continuous flow of working medium 7, 8 two check valves 9, 10, two sensors of the volume and gas analyzers 11, 12, the fuel cell 14, ultracapacitor 15, motor 16, a heat exchanger of the second circuit 17, control unit 13.

4. The power plant according to claim 3, characterized in that in order to ensure autonomy and reduce harmful emissions, operating costs, improve reliability and operational safety, environmental improvements in power plant, heat pump, instead of the fuel cell 14, ultracapacitor 15 and 16 of the electric motor is used arbitrary potential energy converter of hydrogen into electrical or mechanical energy - the internal combustion engine turbine generator, diesel generator, PSTU, turbofan, an MHD generator with PSTU, which allows conversion without substantial transfer the acting thermal power plants, nuclear power plants to hydrogen fuel, hydrogen produced by the generator-heat pump (Fig. 1, blocks 1-13 and 17), and since the combustion of hydrogen (T ~ 3000°C) is water vapor, the addition of water into the combustion chamber and the turbine reduces its temperature, pressure increases and leads to a pair of parameters required for optimal performance of turbines or other consumers.

5. Water vehicle - a ship or submarine, which uses power plant, characterized in that in order to ensure autonomy and reduce harmful emissions, operating costs, improve reliability and safety of operation, power plant made by paragraphs. 3-4 so that the hydrogen generator, heat pump, which supplies engines (turbo or PSTU) traction drive propellers or water jets that perform well as forced circulation of water (sea or river), utilizing its heat through heat exchangers hydrogen generator, located along the sides, in channels (niches), below the waterline, with the appropriate de-icing systems and protection against fouling of heat exchangers, and for reducing acoustic noise and increase efficiency, traction may be water-jets or propellers in circular shaped fairings - fenestronah performed as heat exchangers.

6. Ground or air vehicle - a railway locomotive, car, plane, or helicopter, using the power plant, characterized in that in order to ensure autonomy and reduce harmful emissions, operating costs, improve reliability and safety of operation, power plant made by paragraphs. 3-4 so that the hydrogen generator, heat pump, which supplies traction motors (internal combustion engines, turbine generators, diesel generators, turbofan), which, like the surface of the body of the vehicle include air cooling, forced air pumping, or the oncoming high-speed flow utiliziruyushie warm air in the presence of de-icing systems in a heat exchanger on the surface of the body.

7. Domestic or industrial heating, air conditioning, ventilation, energy buildings, utilizing power plant, characterized in that in order to ensure autonomy and reduce harmful emissions, operating costs, improve reliability and safety of operation, power plant made by paragraphs. 3-4 so that the hydrogen generator heat exchangers and heat pumps use heat: ground (placed in the wells, pile foundations of buildings and structures, ground or coolers), water (local water bodies, groundwater, river water, coastal water and geothermal sources ), air (air cooling), Sun (gelionagrevateli), wind energy, heat or dispose of industrial process plants.

P.S. The proposal for cooperation in the fields of power generation equipment, hydrogen power, alternative energy, renewable energy, electricity, or hydrogen-powered vehicles.

Alexander Bogdanchenko

Alexander Bogdanchenko

Contacts

Mail to: h2energy@i.ua

Sites h2energy.tk,

h2energy2.tk

h2energy.narod.ru,

h2energy.narod2.ru

h2energy.ucoz.ua,

h2energy.ucoz.com

| to home Page |